Water Blocks and Motherboard

This is kind of like a hidden track on a CD I guess. I just wanted to cover a couple of other things I had been up to. Basic stuff and more \'tip of the iceberg\' but just to let you know I hadn\'t been a lazy-gnome.

An Abit IC-7G. My current weapon of choice for the P4C. I went for this board after reading some good reviews and doing some research. I didn\'t get the \'Max3\' version as it wasn\'t available at the time I was gathering the components for the project. As the IC-7G doesn\'t have onboard RAID 0+1 I have been forced to use a PCI RAID card.

One great feature of this board is the way the connectors for the optical drives sit parallel to the boards surface. This has ended up working perfectly for me, as you will see in later articles when I get into the final stage of the project.

Going for a total watercooling solution I popped off the Northbridge heat-sink and fan. Apparently these ones are a bit noisy? I wouldn\'t really know as it didn\'t survive long enough to get tested! All the grunge on the Chipset was cleaned off with Isopropyl Alcohol.

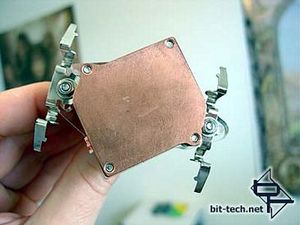

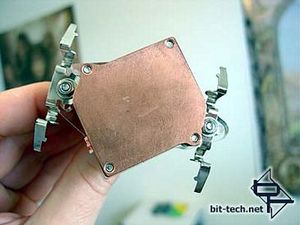

The 875P Canterwood boards come with a tricky set of loops for mounting a HSF. As I already had my old-style DangerDen block and wasn\'t about to shell out for a newfangled one how was I going to mount it? Why, mod it of course!

I removed the steel ring and tossed the heat-sink and fan in my parts box. A comparison between the heights of my waterblock and the discarded heatsink revealed they were practically the same height. Excellent....Bwuhahahahaaaa!

Out with the dremel and it\'s cuttin\' time! I only wanted the clip-part.

I filed the rough edges and drilled a hole in each one. I then got some stainless steel screws and slipped them inside some heat shrink to make them wider and protect the lexan top of the water block.

I then just attached the clips to the usual water block mounting holes with a washer and nut.

Voila! Home-style mounting for an 875P board. Of course, all this was done with careful measuring and a lot of thought (plus some filing and test-fitting) to get it to fit right. Being such a heavy block, and with the torque applied by 3/4\" OD hoses and so on, I didn\'t trust a thermal epoxy solution by itself - hence the modding.

And before any water cooling gurus say anything - I later lapped the blocks to a nice 1200 grit shine!

This is kind of like a hidden track on a CD I guess. I just wanted to cover a couple of other things I had been up to. Basic stuff and more \'tip of the iceberg\' but just to let you know I hadn\'t been a lazy-gnome.

An Abit IC-7G. My current weapon of choice for the P4C. I went for this board after reading some good reviews and doing some research. I didn\'t get the \'Max3\' version as it wasn\'t available at the time I was gathering the components for the project. As the IC-7G doesn\'t have onboard RAID 0+1 I have been forced to use a PCI RAID card.

One great feature of this board is the way the connectors for the optical drives sit parallel to the boards surface. This has ended up working perfectly for me, as you will see in later articles when I get into the final stage of the project.

Going for a total watercooling solution I popped off the Northbridge heat-sink and fan. Apparently these ones are a bit noisy? I wouldn\'t really know as it didn\'t survive long enough to get tested! All the grunge on the Chipset was cleaned off with Isopropyl Alcohol.

The 875P Canterwood boards come with a tricky set of loops for mounting a HSF. As I already had my old-style DangerDen block and wasn\'t about to shell out for a newfangled one how was I going to mount it? Why, mod it of course!

I removed the steel ring and tossed the heat-sink and fan in my parts box. A comparison between the heights of my waterblock and the discarded heatsink revealed they were practically the same height. Excellent....Bwuhahahahaaaa!

Out with the dremel and it\'s cuttin\' time! I only wanted the clip-part.

I filed the rough edges and drilled a hole in each one. I then got some stainless steel screws and slipped them inside some heat shrink to make them wider and protect the lexan top of the water block.

I then just attached the clips to the usual water block mounting holes with a washer and nut.

Voila! Home-style mounting for an 875P board. Of course, all this was done with careful measuring and a lot of thought (plus some filing and test-fitting) to get it to fit right. Being such a heavy block, and with the torque applied by 3/4\" OD hoses and so on, I didn\'t trust a thermal epoxy solution by itself - hence the modding.

And before any water cooling gurus say anything - I later lapped the blocks to a nice 1200 grit shine!

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.